Enkonduko

With the booming of global advertising industry, metal letters has been more and more popular because of its colorfulness, attractiveness, heating-proof, frozen-proof, no deformation, no fadedness (8-10 years color preservation), corrosion proof, rain-proof, and spontaneous combustion proof and some other good features. AD metal letters are made of stainless steel, aluminum, copper or other metal sheet being cut, polished, hemmed, and welded. The core feature of AD metal letters is being rustproof, with long life span and dimensional looks. It’s widely used in LED illuminated billboard, exterior/interior signs, branding, door plate and etc.

Technical Index: | ||

Model No. | CTZG-200W | CTZG-400W |

Lasera Potenco | 200W | 400W |

Laser Fonto | Nd3+: YAG bar Φ7*145mm | Nd3+: YAG bar Φ8*155mm |

Lasera Ondolongo | 1064 nm | |

Laser Tube Qty’ | 1 pc | 2 pcs |

Single-pulse Energy | 80J | 120J |

Pulse Duration | 0.2~20ms | |

Frequency Range | 0.1~50Hz | 0.1~100Hz |

Workable Current | 50~200A | 50~300A |

Welding Spot Diameter | 0.3~1.0mm | 0.3~1.2mm |

Table Size | W1000*L750mm | |

Table Size | W1000*L750mm | |

Laser Arm Stretch | total length 1370mm,strech distance 750mm | |

Fiber Cable Length | 5 meters (work distance of pen mode) | |

Settings Memory | 100 groups | |

Control Panel | 7” color LED touch screen | |

Language Option | English/Chinese | |

Elektroprovizo | 220V/50Hz (220V/60Hz optional) | 380V/50Hz (380V/60Hz optional) |

Power Consumption | Laser: 8KW , Chiller:1KW | Laser:14KW , Chiller:3.3KW |

Dimensions(mm) | Laser &table: 1730*750*1250 Chiller: 480*580*800 (1HP) | Laser & table: 1730*750*1250 Chiller: 1100*650*1350 (3HP) |

Neta Pezo | 305KG | 400KG |

Package Volume | 2.5CBM | 3CBM |

Package Weight | 345KG | 450KG |

Applicable Materials | Stainless Steel, Titanium, Iron, Galvanized sheet | Stainless Steel, 1000 Serial Aluminum, Copper Alloy, Titanium, Iron, Galvanized sheet |

Material Thickness | <=1.5mm | <=2.5mm |

Advantages

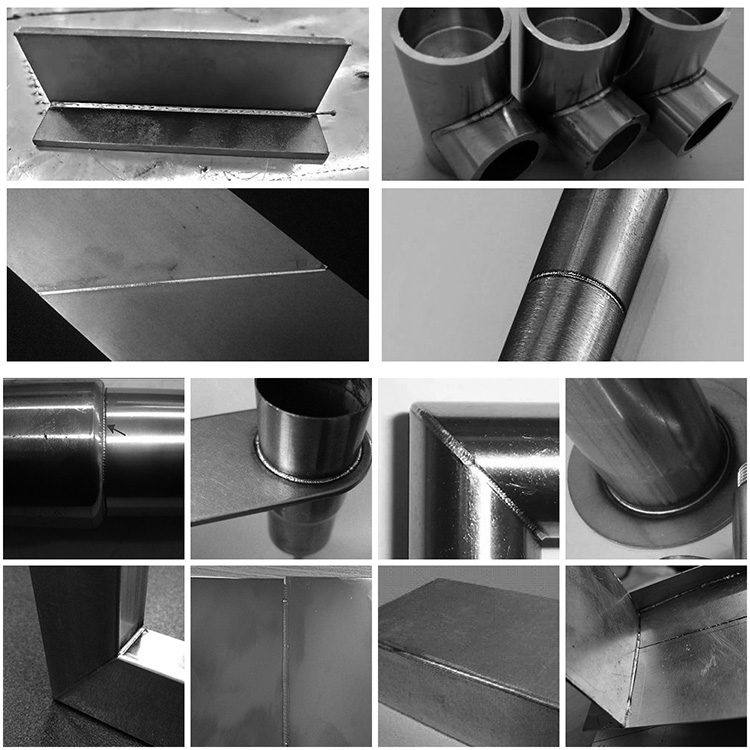

Sample Show

Applicable Industry:

1. Widely applied in the fields of aeronautical and space, mechanism, electron, communication, dynamic,Chemical, automobile manufacture and other industries.

2. The welding of automobile spare parts, such as hydraulic pressure jib, gasoline cleaner, left gas sensor,Electromagnetic valve, and drive starting stator.

3. The close welding of lithium ion batteries, such as mobile phone batteries and power batteries.

4. In metallurgy industry, such as silicon steel plate welding.

5. The welding of engine and engine lamina in application military industry.

6. The precise spot welding of the electronic components and close welding of relay.

7. In electrical equipment industry, such as silicon steel sheet welding, the rotor of the air-conditioner Drive welding, and creepage protection welding.

Applicable Materials:

Materials that can be welded are extensive: cold work alloy steel, hot work alloy steel, nickel tool steel, steel alloy, high tenacity aluminum alloy, etc. Other metals like gold, silver, brass, aluminum-magnesium alloy, titanium, and platinum are also applicable.

Pako